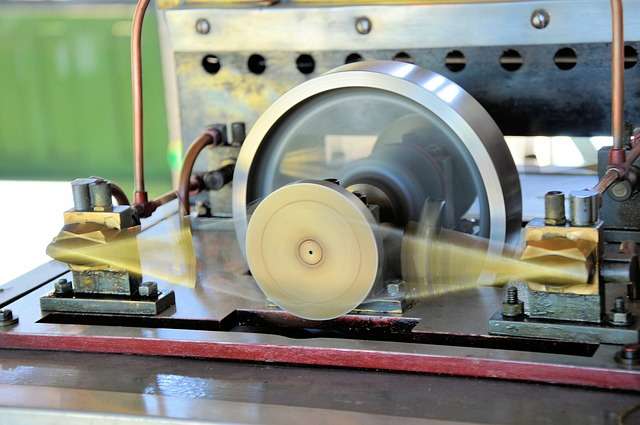

What do you first visualise when you imagine a manufacturing unit? You will think of a big space, large machines and workers. Yes, the noise. There will be machines doing their work at break-neck speed. The workers check the quality of the functioning machines. They ensure that the end product meets the requirements of the clients. A manufacturing facility means more work and repetitive processes. Now, if only the repetitive processes gets done by machines. Then, the humans can concentrate on other important tasks. This is how automation first came into existence. This article will focus on the benefits to manufacturing industry from automation.

History of Automation in Manufacturing Industry

The first record dates back to the golden years of Roman Empire. In those days, water wheels got used to drain water for the farms. Then came the industrial revolution in 1800. Machines substituted human labour in UK and European countries. But it was Henry Ford who first made use of automation in his Ford company. He put together the assembly line in the 1910 as well as 1920s which speeded up the production of cars. The news spread around the globe. It emphasized the importance and benefits to manufacturing industry from automation.

Will you believe that the Fortune Magazine had already published a story with the title? It is “Machines Without Men” and it was a long way back in 1946. This story gave a brief account of the manufacturing industry without workers. True, at that time, the internet, internet of things and mobile access was not yet found.

By 1980s, computer was used in various industrial sectors. This concept gave rise to the usage of computer driven automation in the manufacturing industry.

Benefits Of Industrial Automation

In 2000, the concept of automation became popular. There were many who thought that these machines will substitute human labour. Millions will be thrown out of jobs, and unemployment will rise. However, the fears were unfounded. Automation experts designed manufacturing programs which can do repetitive processes without a murmur or taking rest. They have also designed automation software which can work in co-ordination with human workers.

The benefits to manufacturing industry from automation (two decades ago):

- They can reduce the workplace hazards

- Employ automation robots to work in dangerous environment

- Reduce manual labour for unimportant processes

- Increase productivity and end product quality (consistency)

- Quality improvement through robotics

Some industries such as aviation and real estate require the manufacturing of parts that needs precision. It is impossible for a human to have consistency when working on such components. Automation can help, in this regard, to manufacture similar parts in large number.

When new manufacturing equipment comes to the market, the industrial has to make an investment in purchasing the same. Also, he has to train his workers to use the equipment. However, with automation, the production capabilities are already inbuilt in the manufacturing processes. The workers need to just check if the equipment is functioning as per the demand.

Benefits to Manufacturing Industry from Automation in Recent Times

When machine learning gets embedded in automation manufacturing equipment, the industrialist gets numerous advantages. The program allows the manufacturing team to:

- Identify the errors before starting a large scale production

- Trace the equipment errors before they become full-blown problems

- There is a new program which has gained popularity known as Industrial Internet of Things (IIoT). This program can help a manufacturing equipment to make analytical decisions regarding production. With Industrial Internet of Things, the department managers can track the worker activity, compliance in machines and safety issues of manufacturing floors.

- With machine learning and artificial intelligence, the manufacturing can know the ways to minimise waste in production, save energy etc.

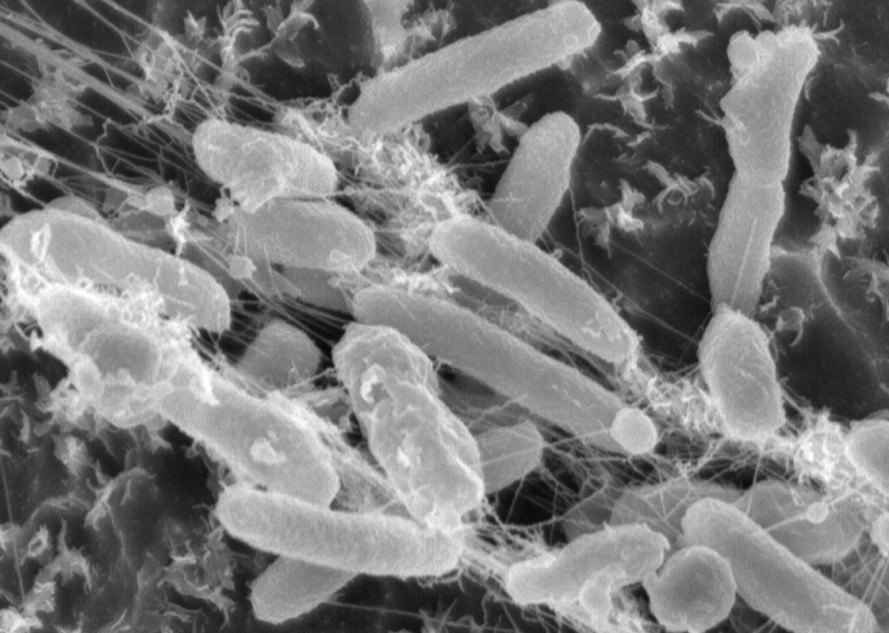

- There are some components, which may have to be manufactured under extreme heat conditions, thus putting human workers at risk. Industrial robots with automation programs are delegated to work under these extreme conditions.

Factors to Consider Before Considering Industrial Automation

You may have been elated by now, after hearing the benefits of automation to manufacturing industry/sector. But as per business experts, these are things to consider when automating a process for your manufacturing unit.

1. Technical

If you are a manufacturer, does your facility have the relevant production units to implement automation? You need to do a complete assessment. Also, please note, there are procedures which can get automated with ease.

Example – soldering and welding

Some processes can get partially automated (drilling as well as filling)

However, you will have to change the entire process if there needs to be a change in driving supplies

2. Budget

Yes, it is well-known that automation can offer significant savings in the long term. But you need to put a considerable investment in the initial stages. Also, you need to consider the processes which have to be first automated. An assessment done with patience by the industry experts will ensure that the change to automation brings sufficient profits.

3. Alternative

Yes, automation may be an alternative to human workers. But will your manufacturing unit benefit from the change? There are some manufacturing components which may not need the automation process and may involve extensive checking of the end products. If you have a similar manufacturing unit, then it is better not to opt for automation.

If you have checked the above factors, and feel that by automation, you can boost your profits, then you need to follow the guidelines as per the Government. The change to automation should follow the industry standard practices along with human labour policies.

Best Industrial Automation Companies In The World

- Siemens

- ABB

- Emerson Process Management

- Rockwell automation

- Schneider Electric

- Honeywell process solutions

- Mitsubishi electric

- Yokogawa electric

- Omron automation

- Danaher Industrial Ltd

Best Indian Industrial Automation Companies

- Peppermint

- Morol Refinery

- Infinite Uptime

- Fabheads Automation

- Matsci Ai

- Things Alive

- Dqap Systems Private Limited

- Jai Balaji Group India

- Yawot

- Xyma Analytics Private Limited

- Accel Controls

- Vararoh

- Lotus Wireless Technologies India Private Limited

- Linkez Technologies Private Limited

- Cratus Automation

- Kitsune Energy

Manufacturing Automation Software In the Globe

- DAQFactory

- FASYS

- FASTSUITE

- Worximity

- Fulcrum

- FactoryTalk

- Ignition Perspective

- XL Productivity Appliance

- Tulip

- MachineMetrics

- Aptean Factory MES

- SensrTrx

- FACTIVITY APS

- Epicor Advanced MES

- DemandCaster

- FactoryLogix

- Shopfloor-Online

- E2 Shop System

- IQMS MES

Conclusion

It is not only manufacturing, but almost all industries have got changed for the better, courtesy, automation. Coupled with the other technologies such as industrial internet of things, machine learning and artificial intelligence, you can set your manufacturing unit on the road to profits and enriching your business coffers.